- Sign In

- |

- Sign Up

- |

- My Quote (0)

- |

- CART (0)

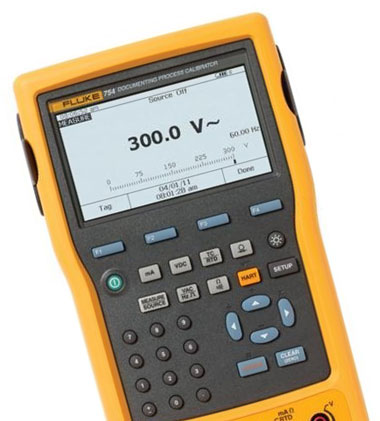

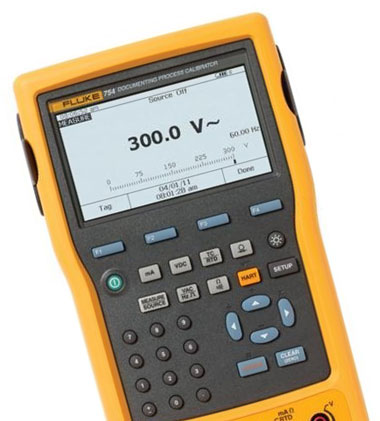

Rugged and compact, this documenting process calibrator is powerful yet easy to use. Ideal for troubleshooting HART instrumentation, the calibrator offers communication and calibration functions in one tool. With a bright display and multi-lingual interface, the calibrator measures pressure, temperature, and electrical signals.

Rugged and compact, this documenting process calibrator is powerful yet easy to use. Ideal for troubleshooting HART instrumentation, the calibrator offers communication and calibration functions in one tool. With a bright display and multi-lingual interface, the calibrator measures pressure, temperature, and electrical signals.

Providing reliable results, this documenting process calibrator monitors, controls, calibrates HART instrumentation, records, and stores results. Simultaneously source and measure capabilities and communicate via industry-standard digital protocols.

Features

Work smarter and faster

Whether you're calibrating instruments, troubleshooting a problem, or running routine maintenance, this documentating process calibrator with HART communication can help you get the job done faster. It does so many different tasks, so quickly and so well, it's the only process calibrator you need to carry. This rugged, reliable integrated communicating calibrator is ideal for calibrating, maintaining, and troubleshooting HART and other instrumentation.

This unit is a power multifunction documenting calibrator that you can use to download procedures, lists, and instructions created with software; or upload data for printing, archiving, and analysis. The powerful built-in HART interface is capable of performing nearly all the day-to-day tasks you now perform with a separate communicator.

In fact, this calibrator does the work of several tools. It sources, simulates and measures pressure, temperature, and electrical signals with one rugged, hand-held device. For documentation, it automates calibration procedures and captures your data, and, of course, helps you meet rigorous standards like ISO 9000, FDA, EPA and OSHA regulations. Plus, the graphical screen, Li-Ion battery for longer life, USB port, and accessories help you work smarter and faster.

Applications

| Measurement Accuracy | |

| Voltage DC | Range/resolution: 100 mV, 3, 30, 300 V 1 year: 0.02% + 0.005 mV, 0.02% + 0.00005, 0.02% + 0.0005, 0.05% + 0.05 V 2 yearss: 0.03% + 0.005 mV, 0.03% + 0.00005, 0.03% + 0.0005, 0.07% + 0.05 V |

| Voltage AC | Range/resolution: 3 V (40 to 500 Hz)/0.001 V 1 year: 0.5% + 0.002, 0.5% + 0.02, 0.5% + 0.2 V 2 years: 1% + 0.004, 1% + 0.04, 1% + 0.2 V |

| Resistance | Range/resolution: 10, 100, Ω, 1, 10 kΩ 1 year: 0.05% + 50, 0.05% + 50, 0.05% + 500 mΩ, 0.1% + 10 Ω 2 years: 0.07% + 70, 0.07% + 70 mΩ, 0.07% + 0.5, 0.15% + 15 Ω |

| Frequency | Range/resolution: 1 to 110/0.01, 110.1 to 1100 Hz/0.1 Hz, 1.101 to 11/0.001, 11.01 to 50 kHz/0.01 kHz 2 years: 0.05, 0.5 Hz, 0.0005, 0.05 kHz |

| Source Accuracy | |

| Voltage DC | Range/resolution: 100 mV, 1, 15 V 1 year: 0.01% + 0.005 mV, 0.01% + 0.00005, 0.01% + 0.0005 V 2 years: 0.015% + 0.005 mV, 0.015% + 0.0005, 0.015% + 0.0005 V |

| Current DC | Range/resolution: 22.000 mA (source), Current sink (simulate) 1 year: 0.01% + 0.003, 0.02% + 0.007 mA 2 years: 0.02% + 0.003, 0.04% + 0.007 mA |

| Resistance | Range/Resolution: 10, 100 Ω, 1, 10 kΩ 1 year: 0.01% + 10, 0.01% + 20 mΩ, 0.02% + 0.2, 0.02% + 3 Ω 2 years: 0.015% + 15, 0.015% + 30 mΩ, 0.03% + 0.3, 0.03% + 5 Ω |

| Frequency | Range/resolution: 0.1 to 10.99, 0.01 to 10.99, 11.00 to 109.99, 110.0 to 1099.9 Hz, 1.100 to 21.999, 22.000 to 50 kHz 2 years: 0.01, 0.01, 0.1, 0.1 Hz, 0.002, 0.005 kHz |

| General Specifications | |

| Environmental Conditions | Operating temperature: 14 to 122°F (-10 to 50°C) Storage temperature: -20 to 140°F(-20 to 60°C) Dust/water resistance: Meets IP52, IEC 529 Operating altitude: 9842' (3000 m) above mean sea level |

| Agency Approvals | CAN/CSA C22.2 No 1010.1-92, ASNI/ISA S82.01-1994, UL3111, and EN610-1:1993 |

| Data Storage Capacity | One week of calibration procedures results |

| Battery | Type: Internal battery pack Li-ion (7.2 V, 4400 mAh, 30 Wh) Life: >8 hours typical |

| Dimensions | 5.4 x 9.6 x 2.5" (136 x 245 x 63 mm) |

| Weight | 2.7 lbs (1.23 kg) |

HART, the Highway Addressable Remote Transducer protocol, uses a 1200 baud Frequency Shift Keying (FSK) signal to superimpose digital information on the conventional 4 to 20 mA analog signal.

HART is an industry standard developed to define the communications protocol between intelligent field devices and a control system, HART is the most widely used digital communication protocol in the process industry. More than five million HART field instruments are installed in more than 100,000 plants worldwide. The HART protocol:

Process plants have taken advantage of smart transmitters, the need for a new generation of calibrators has emerged - calibrators that can communicate via industry standard digital protocols. This process calibrator combines HART communication capability in a documenting process calibrator to deliver an integrated communicating calibrator. This rugged, reliable tool is ideal for calibrating, maintaining, and troubleshooting HART instrumentation. This process calibrator offers:

The field calibrator for HART instruments that's both powerful and easy to use

This process calibrator offers the most complete HART implementation of any process calibrator. This process calibrator:

This process calibrator is designed to take on nearly all the day-to-day tasks you now perform with a separate communicator. In fact, it offers many of the communication capabilities of the 475 HART communicator except for the DD interpreter, which can read command set libraries from any HART supplier. This is not necessary for daily HART maintenance.

Pressure transmitter manufacturers have improved the accuracy and technology designed into these smart pressure measurement devices. Many conventional calibration tools have become inadequate or simply unable to test and calibrate these high accuracy pressure transmitters. Better test solutions are required.

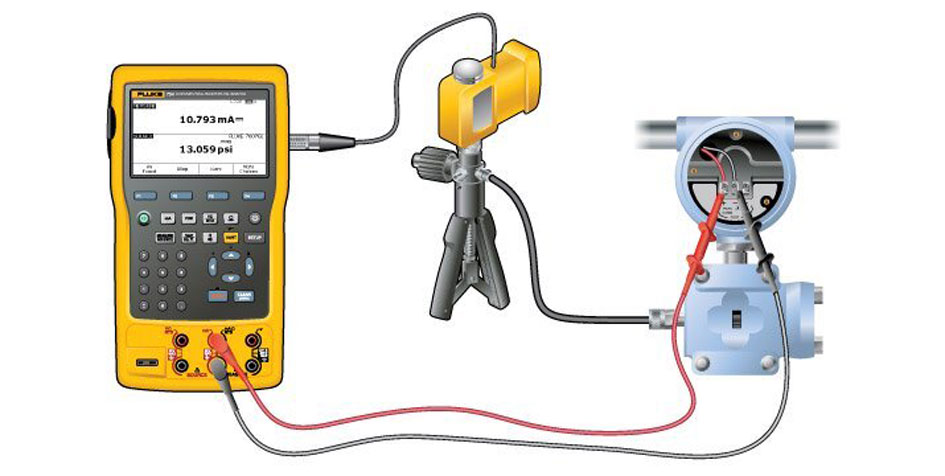

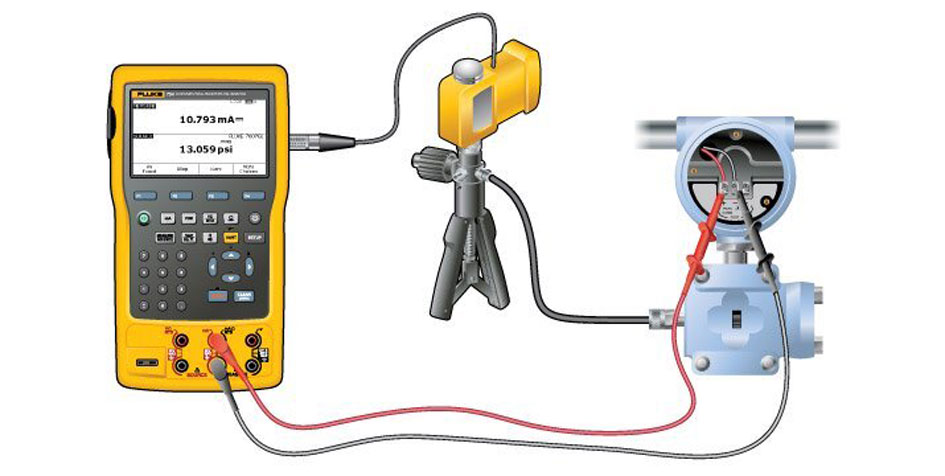

Verifying and documenting the performance and adjusting a HART smart pressure transmitter can require a bucket full of tools. Performing this task with a HART enabled calibrator like this process calibrator simplifies the task and reduces what you need to carry.

Before going to the field, install the pressure module adapter to the hand pump with thread seal. Once the adapter is properly installed on the pump, changing modules to different pressure ranges is a snap, no tools required.

To get the accuracy needed to test these new high accuracy transmitters, match the pressure measurement standard range closely to the device tested. For example, use a 100 psi pressure module to calibrate and test a transmitter ranged at 100 psi. Industry standards suggest the measurement standard should be 4 to 10 times more accurate than the device being tested, so best-in-class accuracy is required.

This Documenting Process Calibrator-HART utilizes the 750P series pressure module and has the HART functionality built in to enable smart trims on transmitters. It can also document transmitter performance before and after adjustment and calculate pass/fail errors.

To perform the test:

Fluke 754: The HART calibrator that is easy to use.

Versatile HART protocol support

This process calibrator supports the commands contained in HART protocol version 5.7.

This process calibrator supports a substantial set of HART instructions:

Today's 754 supports device-specific instructions for a variety of popular instruments. Additional support may be added periodically with a simple software update available on diskette or via download for a modest upgrade fee.

| Manufacturer | Pressure Instruments | Temperature Instruments | Coriolis Instruments |

| ABB/Kent-Taylor | 600T | 658T1 | |

| ABB/Hartmann & Braun | Contrans P1, AS 800 Series | ||

| Endress & Hauser | CERABAR S, CERABAR M, DELTABAR S | TMT 1221, TMT 1821, TMT 1621 | |

| Foxboro Eckardt | TI/RTT201 | ||

| Foxboro/Invensys | I/A Pressure | ||

| Fuji | FCX, FCXAZ | FRC | |

| Honeywell | ST3000 | STT25T1, STT25H1 | |

| Micro Motion | 2000, 2000IS, 9701, 9712, 9739 | ||

| Moore Products | 3441 | ||

| Rosemount | 1151, 2088, 3001C, 3051, 3051S | 3044C, 644, 3144, 3244, 3144P | |

| Siemens | SITRANS P DS | ||

| SMAR | SITRANS P DS, SITRANS P ES | ||

| Viatran | LD301 | TT3011 | |

| Wika | UNITRANS | ||

| Yokogawa | EJA | YTA 110, 310 and 320 |

1Sensor trim not supported

HART Operating Modes Supported

Click on a category to view a selection of compatible accessories with the Fluke 754 Documenting Process Calibrator with HART communication.

| Measurement Accuracy | |

| Voltage DC | Range/resolution: 100 mV, 3, 30, 300 V 1 year: 0.02% + 0.005 mV, 0.02% + 0.00005, 0.02% + 0.0005, 0.05% + 0.05 V 2 yearss: 0.03% + 0.005 mV, 0.03% + 0.00005, 0.03% + 0.0005, 0.07% + 0.05 V |

| Voltage AC | Range/resolution: 3 V (40 to 500 Hz)/0.001 V 1 year: 0.5% + 0.002, 0.5% + 0.02, 0.5% + 0.2 V 2 years: 1% + 0.004, 1% + 0.04, 1% + 0.2 V |

| Resistance | Range/resolution: 10, 100, Ω, 1, 10 kΩ 1 year: 0.05% + 50, 0.05% + 50, 0.05% + 500 mΩ, 0.1% + 10 Ω 2 years: 0.07% + 70, 0.07% + 70 mΩ, 0.07% + 0.5, 0.15% + 15 Ω |

| Frequency | Range/resolution: 1 to 110/0.01, 110.1 to 1100 Hz/0.1 Hz, 1.101 to 11/0.001, 11.01 to 50 kHz/0.01 kHz 2 years: 0.05, 0.5 Hz, 0.0005, 0.05 kHz |

| Source Accuracy | |

| Voltage DC | Range/resolution: 100 mV, 1, 15 V 1 year: 0.01% + 0.005 mV, 0.01% + 0.00005, 0.01% + 0.0005 V 2 years: 0.015% + 0.005 mV, 0.015% + 0.0005, 0.015% + 0.0005 V |

| Current DC | Range/resolution: 22.000 mA (source), Current sink (simulate) 1 year: 0.01% + 0.003, 0.02% + 0.007 mA 2 years: 0.02% + 0.003, 0.04% + 0.007 mA |

| Resistance | Range/Resolution: 10, 100 Ω, 1, 10 kΩ 1 year: 0.01% + 10, 0.01% + 20 mΩ, 0.02% + 0.2, 0.02% + 3 Ω 2 years: 0.015% + 15, 0.015% + 30 mΩ, 0.03% + 0.3, 0.03% + 5 Ω |

| Frequency | Range/resolution: 0.1 to 10.99, 0.01 to 10.99, 11.00 to 109.99, 110.0 to 1099.9 Hz, 1.100 to 21.999, 22.000 to 50 kHz 2 years: 0.01, 0.01, 0.1, 0.1 Hz, 0.002, 0.005 kHz |

| General Specifications | |

| Environmental Conditions | Operating temperature: 14 to 122°F (-10 to 50°C) Storage temperature: -20 to 140°F(-20 to 60°C) Dust/water resistance: Meets IP52, IEC 529 Operating altitude: 9842' (3000 m) above mean sea level |

| Agency Approvals | CAN/CSA C22.2 No 1010.1-92, ASNI/ISA S82.01-1994, UL3111, and EN610-1:1993 |

| Data Storage Capacity | One week of calibration procedures results |

| Battery | Type: Internal battery pack Li-ion (7.2 V, 4400 mAh, 30 Wh) Life: >8 hours typical |

| Dimensions | 5.4 x 9.6 x 2.5" (136 x 245 x 63 mm) |

| Weight | 2.7 lbs (1.23 kg) |

HART, the Highway Addressable Remote Transducer protocol, uses a 1200 baud Frequency Shift Keying (FSK) signal to superimpose digital information on the conventional 4 to 20 mA analog signal.

HART is an industry standard developed to define the communications protocol between intelligent field devices and a control system, HART is the most widely used digital communication protocol in the process industry. More than five million HART field instruments are installed in more than 100,000 plants worldwide. The HART protocol:

Process plants have taken advantage of smart transmitters, the need for a new generation of calibrators has emerged - calibrators that can communicate via industry standard digital protocols. This process calibrator combines HART communication capability in a documenting process calibrator to deliver an integrated communicating calibrator. This rugged, reliable tool is ideal for calibrating, maintaining, and troubleshooting HART instrumentation. This process calibrator offers:

The field calibrator for HART instruments that's both powerful and easy to use

This process calibrator offers the most complete HART implementation of any process calibrator. This process calibrator:

This process calibrator is designed to take on nearly all the day-to-day tasks you now perform with a separate communicator. In fact, it offers many of the communication capabilities of the 475 HART communicator except for the DD interpreter, which can read command set libraries from any HART supplier. This is not necessary for daily HART maintenance.

Pressure transmitter manufacturers have improved the accuracy and technology designed into these smart pressure measurement devices. Many conventional calibration tools have become inadequate or simply unable to test and calibrate these high accuracy pressure transmitters. Better test solutions are required.

Verifying and documenting the performance and adjusting a HART smart pressure transmitter can require a bucket full of tools. Performing this task with a HART enabled calibrator like this process calibrator simplifies the task and reduces what you need to carry.

Before going to the field, install the pressure module adapter to the hand pump with thread seal. Once the adapter is properly installed on the pump, changing modules to different pressure ranges is a snap, no tools required.

To get the accuracy needed to test these new high accuracy transmitters, match the pressure measurement standard range closely to the device tested. For example, use a 100 psi pressure module to calibrate and test a transmitter ranged at 100 psi. Industry standards suggest the measurement standard should be 4 to 10 times more accurate than the device being tested, so best-in-class accuracy is required.

This Documenting Process Calibrator-HART utilizes the 750P series pressure module and has the HART functionality built in to enable smart trims on transmitters. It can also document transmitter performance before and after adjustment and calculate pass/fail errors.

To perform the test:

Fluke 754: The HART calibrator that is easy to use.

Versatile HART protocol support

This process calibrator supports the commands contained in HART protocol version 5.7.

This process calibrator supports a substantial set of HART instructions:

Today's 754 supports device-specific instructions for a variety of popular instruments. Additional support may be added periodically with a simple software update available on diskette or via download for a modest upgrade fee.

| Manufacturer | Pressure Instruments | Temperature Instruments | Coriolis Instruments |

| ABB/Kent-Taylor | 600T | 658T1 | |

| ABB/Hartmann & Braun | Contrans P1, AS 800 Series | ||

| Endress & Hauser | CERABAR S, CERABAR M, DELTABAR S | TMT 1221, TMT 1821, TMT 1621 | |

| Foxboro Eckardt | TI/RTT201 | ||

| Foxboro/Invensys | I/A Pressure | ||

| Fuji | FCX, FCXAZ | FRC | |

| Honeywell | ST3000 | STT25T1, STT25H1 | |

| Micro Motion | 2000, 2000IS, 9701, 9712, 9739 | ||

| Moore Products | 3441 | ||

| Rosemount | 1151, 2088, 3001C, 3051, 3051S | 3044C, 644, 3144, 3244, 3144P | |

| Siemens | SITRANS P DS | ||

| SMAR | SITRANS P DS, SITRANS P ES | ||

| Viatran | LD301 | TT3011 | |

| Wika | UNITRANS | ||

| Yokogawa | EJA | YTA 110, 310 and 320 |

1Sensor trim not supported

HART Operating Modes Supported

Click on a category to view a selection of compatible accessories with the Fluke 754 Documenting Process Calibrator with HART communication.