- Sign In

- |

- Sign Up

- |

- My Quote (0)

- |

- CART (0)

Capture accurate measurements with this infrared camera that provides superior image quality and a built-in laser distance meter that calculates and displays the distance from your target and automatically adjusts the focus. Rugged and versatile, the camera features interchangeable smart lenses to conduct inspections effortlessly.

Capture accurate measurements with this infrared camera that provides superior image quality and a built-in laser distance meter that calculates and displays the distance from your target and automatically adjusts the focus. Rugged and versatile, the camera features interchangeable smart lenses to conduct inspections effortlessly.

With a rugged pistol-grip design, this infrared camera enables thermographers to assess and solve mission-critical problems before they result in downtime. Edit and analyze images directly on the camera featuring the SuperResolution mode that provides four times the standard resolution.

Features

Applications

Fluke Connect™ Compatible

We recognize that it’s not one approach for all—each industry, business and success measure is unique. Optimally engineered, Fluke cameras are aligned to drive efficiency through the latest in thermography technology advancements. They offer everything needed for industrial professionals to safely, quickly and easily find, assess and solve mission-critical problems before they result in downtime, become costly or even disastrous.

When conducting infrared inspections, high-quality images that allow for better analysis, presentation, and professionalism are essential.

With a sharply focused image, there is a distinct contrast between areas of varying thermal energy on the surface being inspected. This allows the individual detector elements (also known as pixels) to clearly report the intensity of the energy being focused on them.

When the focus is poor, the incoming energy isn't as concentrated on individual detectors, and their response is skewed. This can lead to temperature measurements that are significantly off, resulting in expensive downtime and possible safety hazards.

Thermal imagers are made with 100% diamond-turned germanium lenses covered with a specialty coating, providing premium quality images.

LaserSharp Auto Focus allows you to select and focus on a specific target

Easily choose and focus on your target

LaserSharp™ Auto Focus uses a built-in laser distance meter that provides both speed and precision. The laser-driven target detection pinpoints the target while the camera focuses to capture a precise, high-quality image. With LaserSharp Auto Focus, you can:

Choose multiple targets at different distances

MultiSharp™ Focus takes multiple images from different focal distances and combines them into one clear image. With a simple point and shoot, you can go from being completely out of focus, to complete focus, throughout the field of view. With MultiSharp:

1.Middleground in focus

2.Foreground in focus

3.Background in focus

Shoot from a distance

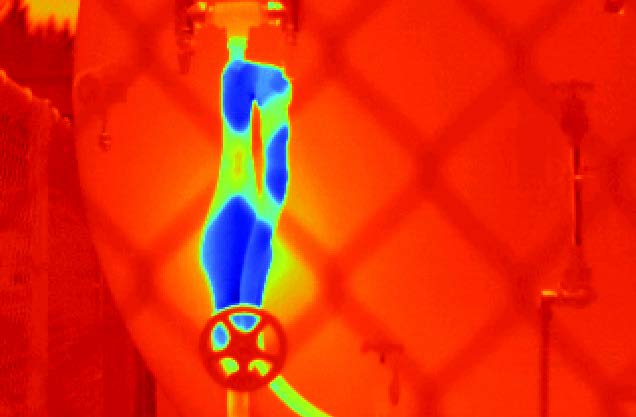

Infrared inspections can take you into multiple types of environments with many types of equipment. Interchangeable lenses that require no calibration give you the versatility and the image quality needed to conduct inspections in almost any environment.

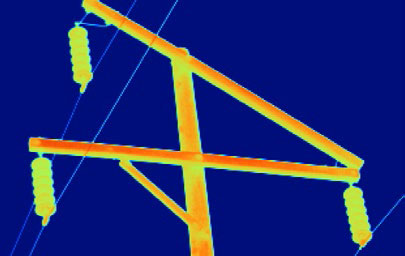

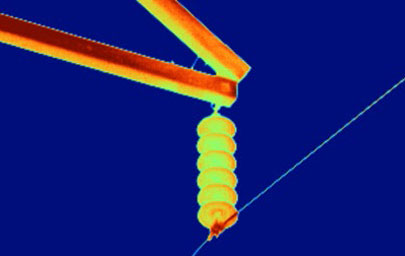

High voltage power pole, captured with a TiX560 camera and standard lens

The same power pole captured from the same distance, but with a 2x telephoto lens

The same power pole captured from the same distance, but with a 4x telephoto lens

Whether you are troubleshooting or conducting maintenance inspections, having easy access to more information faster is always a big benefit.

Document information on the equipment you're inspecting

With IR PhotoNotes™, voice or text annotation, you can easily document critical information about each piece of equipment and its location. Each "note" attaches to the image, so you never have to search or match up notes to images.

|

|

Image Info | |

| IR Sensor Size | 320 x 240 |

| Distance to Target | 0.69 m |

Main Image Markers | |

| Name | Temperature |

| Centerpoint | 29.1°C |

Capture digital and infrared images at once

IR Fusion™ technology combines visible light and an infrared image into one, giving you better clarity.

IR Fusion picture-in-picture mode: Ironbow palette

IR Fusion picture-in-picture mode: AutoBlend

IR Fusion color alarm

Seven benefits of on-site infrared inspections

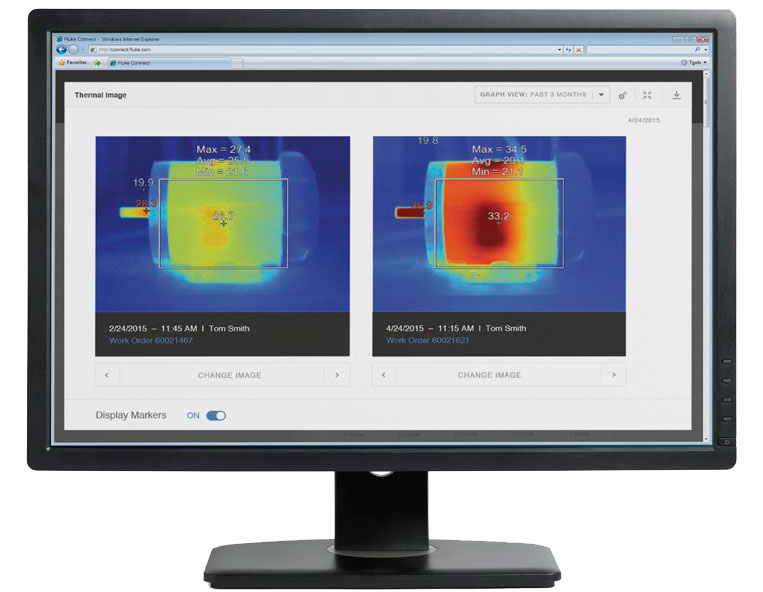

Review thermal images side by side, making it easy to compare today's reading with the baseline or other historical images.

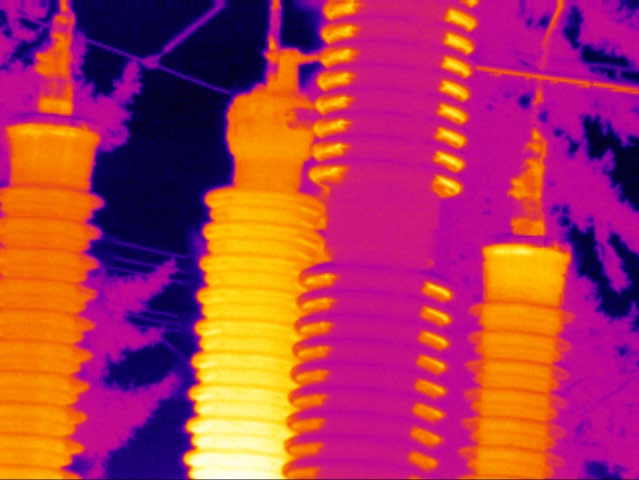

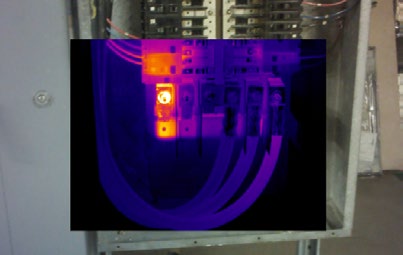

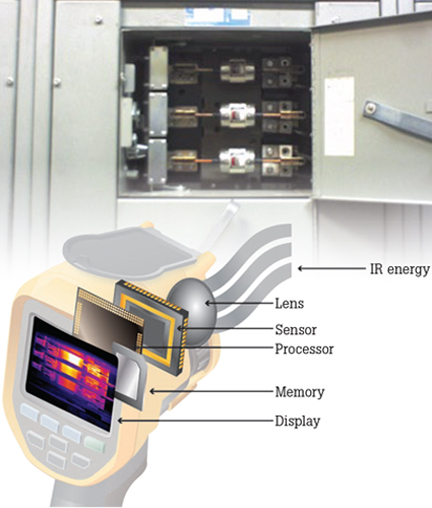

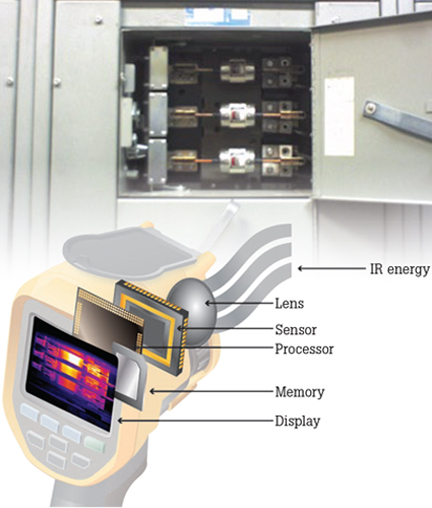

Today’s thermal imagers have become a realistic solution for everyday electrical maintenance as they are rugged, easy to use, and much more affordable than even just a few years ago. It's a straight-forward process, where a qualified technician or electrician points the thermal imager at the equipment in question and scans the immediate area, looking for unexpected hot spots. The imager produces a live image of the heat emitted from the equipment and with the quick squeeze of the trigger, a thermal image is captured. When the inspection is complete, the image is uploaded to a computer, Apple®, iPhone® or iPad® for closer analysis, reporting, and future trending.

There are a few basic how-tos to consider... electrical load, safety, and emissivity. In this application note, we walk you through these, as well as the Top 5 Checklist, and much more.

Read the Application Note

Facilities maintenance professionals face a wide range of challenges, from electrical and mechanical equipment uptime to overall safety concerns. It’s critical to maintain facilities and the associated assets at peak performance. Let's review the issues faced by maintenance managers, IT support, and electrical/mechanical technicians. Along with the Fluke solutions that offer to save you time and money while increasing efficiency and safety. Fluke makes reliable, rugged and accurate tools to maintain electromechanical systems, motors, pumps, electrical distribution systems and more to keep your world up and running.

Learn More

| Key Features | |

| Infrared Resolution | 640 x 480 (307,200 pixels) |

| SuperResolution | Yes, in software. Captures and combines 4x the data to create a 1280 x 960 image |

| IFOV with standard lens (spatial resolution) | 0.93 mRad, D:S 1065:1 |

| Field of View | 34 x 24° |

| Minimum Focus Distance | Approximately 6" (15 cm) |

| MultiSharp Focus | Yes, focused near and far, throughout the field of view |

| LaserSharp Auto Focus | Yes, for consistently in-focus images. Every. Single. Time |

| Laser Distance Meter | Yes, calculates distance to the target for precisely focused images and displays distance on screen |

| Advanced Manual Focus | Yes |

| Wireless Connectivity | Yes, to PC, iPhone® and iPad® (iOS 4s and later), Android™ 4.3 and up, and WiFi to LAN (where available) |

| Fluke Connect App Compatible | Yes, connect your camera to your smartphone, and images taken automatically upload to the Fluke Connect app for saving and sharing |

| Fluke Connect Assets | Through the desktop, assign images to assets, easily compare measurement types in one location and create reports |

| Fluke Connect Instant Cloud Upload | Yes, connect your camera to your building’s WiFi network, and images taken automatically upload to the Fluke Connect system for viewing on your smartphone or PC |

| Fluke Connect Instant Server Upload | Yes |

| IR-Fusion technology | Yes, adds the context of the visible details to your infrared image |

| Ruggedized Touchscreen Display | 3.5" (8.89 cm) landscape, 640 x 480 LCD |

| Ergonomic Design | Pistol-grip design for one-handed use |

| Thermal Sensitivity (NETD) | ≤0.05°C at 30°C target temperature (50 mK) |

| Level and Span | Smooth auto and manual scaling |

| Touchscreen Adjustable Level/Span | Yes. Span and level can be easily and quickly set by simply touching the screen |

| Fast Auto-Rescale in Manual Mode | Yes |

| Span | Minimum in manual mode: 2.0°C (3.6°F) Minimum in in auto mode: 3.0°C (5.4°F) |

| Built-in Digital Camera (Visible Light) | 5 MP |

| Laser Pointer | Yes |

| LED Light (Torch) | Yes |

| Digital Zoom | 2x and 4x |

| Data Storage and Image Capture | |

| Extensive Memory Options | Removable 4 GB micro SD memory card, 4 GB internal flash memory, save to USB flash drive capability, upload to Fluke Cloud™ for permanent storage |

| Image Capture, Review, Save Mechanism | One-handed image capture,review, and save capability |

| Image File Formats | Non-radiometric (.bmp) or (.jpeg) or fully-radiometric (.is2); no analysis software required for non-radiometric (.bmp, .jpg and .avi) files |

| Memory Review | Thumbnail and fullscreen review |

| Software | SmartView® software - full analysis and reporting software and Fluke Connect® system |

| Export File Formats with SmartView® Software | Bitmap (.bmp), GIF, JPEG, PNG, TIFF |

| Voice Annotation | 60 seconds maximum recording time per image; reviewable playback on camera, optional bluetooth headset available but not required |

| IR-PhotoNotes™ | Yes (5 images) |

| Text Annotation | Yes |

| Video Recording | Standard and radiometric |

| File Formats Video | Non-radiometric (MPEG - encoded .AVI) and fully-radiometric (.IS3) |

| Streaming Video (Remote Display) | Yes, see the live stream of the camera display on your PC, smartphone, or TV monitor. Via USB, WiFi hotspot, or WiFi network to SmartView® software on a PC; via WiFi hotspot to the Fluke Connect® app on a smartphone; or via HDMI to a TV monitor |

| Remote Control Operation | Yes, through SmartView® software or Fluke Connect® mobile app |

| Auto Capture (Temperature and Interval) | Yes |

| Temperature Measurement | |

| Temperature Measurement Range (Not Calibrated Below -10°C) | ≤14 to 1832°F (-10 to 1000°C) |

| Accuracy | ±2°C or 2% (at 25°C nominal, whichever is greater) |

| Thermal Sensitivity (NETD) | ≤0.05°C at 30°C target temp (50 mK) |

| On-Screen Emissivity Correction | Yes (both value and table) |

| On-Screen Reflected Background Temperature Compensation | Yes |

| On-Screen Transmission Correction | Yes |

| Line Temperature Graph | Yes |

| Smart Lenses | |

| Macro-25 Micron Lens: 25 MAC2 | Yes |

| 2 x Telephoto Lens: TELE 2 | Yes |

| 4 x Telephoto lens: TELE4 | Yes |

| Wide angle lens: WIDE 2 | Yes |

| Color Palettes | |

| Standard | 9: rainbow, ironbow, blue-red, high contrast, amber, amber inverted, hot metal, grayscale, grayscale inverted |

| Ultra Contrast™ | 9: rainbow, ironbow, blue-red, high contrast, amber, amber inverted, hot metal, grayscale, grayscale inverted |

| General Specifications | |

| Color Alarms (Temperature Alarms) | High temperature, low temperature, and isotherms (within range) |

| Infrared Spectral Band | 7.5 μm to 14 μm (long wave) |

| Temperature | Operating: 14 to 122°F (-10 to 50°C) Storage: -4 to 122°F (-20 to 50°C) without batteries |

| Relative Humidity | 10 to 95% non-condensing |

| Center-Point Temperature Measurement | Yes |

| Spot Temperature | Hot and cold spot markers |

| User-Definable Spot Markers | 3 user-definable spot markers |

| Battery | Type: 2 x lithium ion smart battery packs with five-segment LED display to show charge level Life: 2 to 3 hours per battery (Actual life varies depending on settings and usage) Charge time: 2.5 hours to full charge Charging system: Two-bay battery charger or in-imager charging |

| AC Operation | AC operation with included power supply (100 to 240 V AC, 50/60 Hz) |

| Power Saving | User selectable sleep and power off modes |

| Safety | IEC 61010-1: Overvoltage category II, Pollution Degree 2 |

| Electromagnetic Compatibility | IEC 61326-1: Basic EM environment. CISPR 11: Group 1, Class A |

| US FCC | CFR 47, Part 15 Subpart C Sections 15.207, 15.209, 15.249 |

| Vibration | 0.03 g2/Hz (3.8 g), 2.5 g IEC 68-2-6 |

| Shock | 25 g, IEC 68-2-29 |

| Drop | Engineered to withstand 6.5' (2 m) drop with standard lens |

| Enclosure Rating | IEC 60529: IP54 (protected against dust, limited ingress; protection against water spray from all directions) |

| Dimensions | 10.9 x 4.8 x 6.5" (27.7 x 12.2 x 16.7 cm) |

| Weight | 2.3 lbs (1.04 kg) |

|

|

|

||

| Model | Fluke Ti480 PRO | Fluke Ti401 PRO | Fluke Ti300+ | |

|---|---|---|---|---|

| Infrared Resolution | 640 x 480 (307,200 pixels) | 640 x 480 (307,200 pixels) | 320 x 240 (76,800 pixels) | |

| Super Resolution | Yes, in software. Captures and combines 4x the data to create a 1280 x 960 image | |||

| IFOV (Spatial Resolution) | 0.93 mRad | 0.93 mRad | 1.85 mRad | |

| Field of View | 34 x 24° | 34 x 24° | 34 x 24° | |

| Distance to Spot | 1065:1 | 1065:1 | 532:1 | |

| Thermal Sensitivity* | ≤0.05 at 30°C target temperature (50 mK) | ≤0.075 at 30°C target temperature (75 mK) | ≤0.075 at 30°C target temperature (75 mK) | |

| Temperature Range | -4 to 1832°F (-20 to 1000°C) | -4 to 1202°F (-20 to 650°C) | -4 to 1202°F (-20 to 650°C) | |

| MultiSharp™ Focus | ||||

| LaserSharp™ Auto Focus | LaserSharp™ Auto Focus for consistently in-focus images | |||

| Manual Focus | ||||

| Laser Distance Meter | Yes, calculates distance to the target for precisely focused images and displays distance on screen | |||

| Optional Lenses | Pre-calibrated smart optional lenses: wide angle, 2x and 4x telephoto, macro-25 micron | |||

| Wireless Connectivity** | Fluke Connect™ app compatible. Wireless connectivity to PC, iPhone® and iPad® (iOS 4s and later), Android™ 4.3 and up, and WiFi to LAN | |||

| IR-Fusion® | Five modes of image blending (AutoBlend™ mode, Picture-in- Picture (PIP), IR/Visible alarm, Full IR, Full visible light) add the context of the visible details to your infrared image | |||

| Display | 3.5" touchscreen 640 x 480 LCD | 3.5" touchscreen 640 x 480 LCD | 3.5" touchscreen 640 x 480 LCD | |

| Design | Pistol-grip design for one-handed use | |||

| Frame Rate | 60 or 9 Hz versions | 60 or 9 Hz versions | 60 or 9 Hz versions | |

| Software | Full analysis and reporting software with access to Fluke Connect desktop | |||

| Voice Annotation | 60 seconds maximum recording time per image, reviewable playback on camera; Bluetooth headset optional, but not required | |||

| Text Annotation | Yes, including standard shortcuts as well as user programmable options | |||

| Video Recording | Standard and radiometric | |||

| Streaming Video (Remote Display) | Yes, see the live stream of the camera display on your PC, smartphone, or TV monitor. Via USB, WiFi hotspot, or WiFi network to Fluke Connect Desktop software on a PC; via WiFi hotspot to the Fluke Connect™ app on a smartphone; or via HDMI to a TV monitor | |||

| Remote Control Operation | Yes, through Fluke Connect™ mobile app | |||

| Alarms | High temperature, low temperature, and isotherms (within range) | |||

| Warranty | Two-years (standard), extended warranties are available | |||

*Best possible **Fluke Connect™ not available in all countries

Fluke engineers have delivered an innovative mobile platform and tool that helps solve everyday problems, allowing you to instantly document measurements, retrieve historical data, and share live measurements with your team. All handled by the Android™ or iOS smart phone you already carry.

Fluke Connect with ShareLive™ video call is the only wireless measurement system that lets you stay in contact with your entire team without leaving the field. The Fluke Connect mobile app is works with over 20 different Fluke products - the largest suite of connected test tools in the world.

Make the best decisions faster than ever before by viewing temperature, mechanical, electrical and vibration measurements for each equipment asset in one place. Get started saving time and increasing your productivity.

Whether you choose a simple point-and-shoot model or a high-end thermal imager with all the bells and whistles, here are some key features and specs you should consider:

With a variety of focus mechanisms to choose from, it is important to take into account your skill level as well as the application in selecting a focus type. Here are the common focus mechanisms:

The highest and lowest temperature you encounter in your inspection determines the temperature range you need from your thermal imager. Or, select a camera with a wide temperature range that automatically selects the range based on your scene, or allows you to manually select the temperature range.

A camera that lets you change lenses increases your versatility, allowing you to inspect many more types of equipment and situations. There are lots of choices for lots of applications—standard, wide angle, telephoto, and macro.

Save infrared and digital images and in some cases voice notes to internal memory, a removable SD card, or to a USB flash drive. It’s important to have the flexibility to save images and additional related data to different media for backup or sharing.

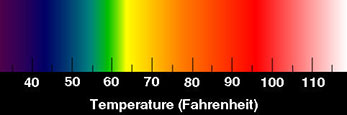

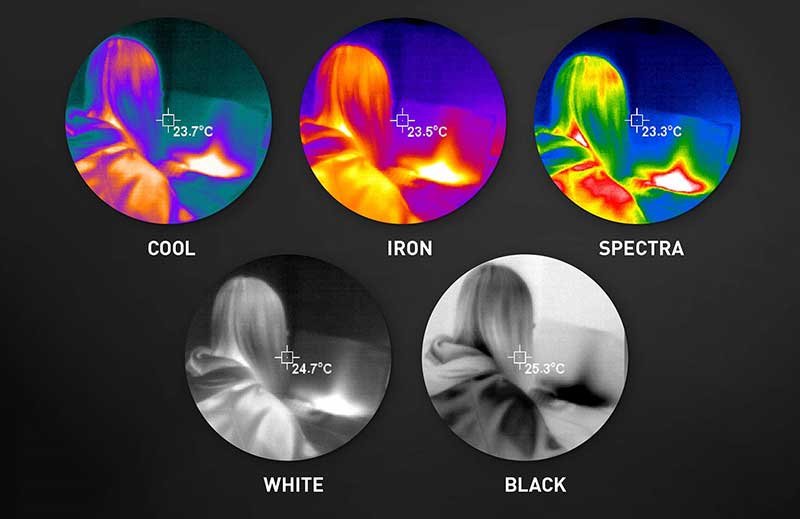

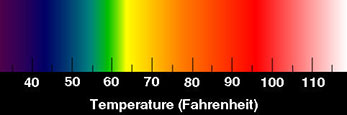

Slight differences are easier to see with a monochromatic palette, such as grayscale or amber. High contrast palettes can make it easier to quickly find obvious anomalies. You should be able to change the palette in the camera or in the software.

Use these to quickly highlight areas outside your normal temperature ranges.

Low emissivity surfaces, such as shiny metals, can reflect infrared energy from other objects and throw off your image and your measurement accuracy. So, look for the option to adjust parameters when choosing an imager.

Mark specific temperatures on your image to compare simultaneous temperatures from multiple points on the same image.

Look for a battery with useful features such a charge level indicator. Nothing is worse than starting an inspection with no idea of the battery status. Also consider long battery life and quick charging ability.

Check out the different color palettes available on your thermal imager!

View your home through the eyes of a thermal imager and and see where the hot and cold spots are.

By Sat Sandhu, Fluke

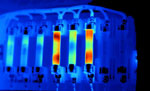

Electronic circuits and components come in a variety of shapes and forms. All electronics operate with current flowing, which in turn leads to power dissipation. This power dissipation manifests itself primarily in the form of heat. Hence a key factor in the design, tests, verification and troubleshooting of all electronics, is heat management. With increasing circuit complexity and or reduction in size, heat management of electronics is taking on a more significant role in the design phase and also in the subsequent phases of test, verification and troubleshooting.

Thermal imaging cameras (TI) are an ideal tool to use in mapping out the heat patterns on electronic circuits and components. Two major advantages of Thermal imaging over contact temperature measurement devices are:

If you would like to learn more about:

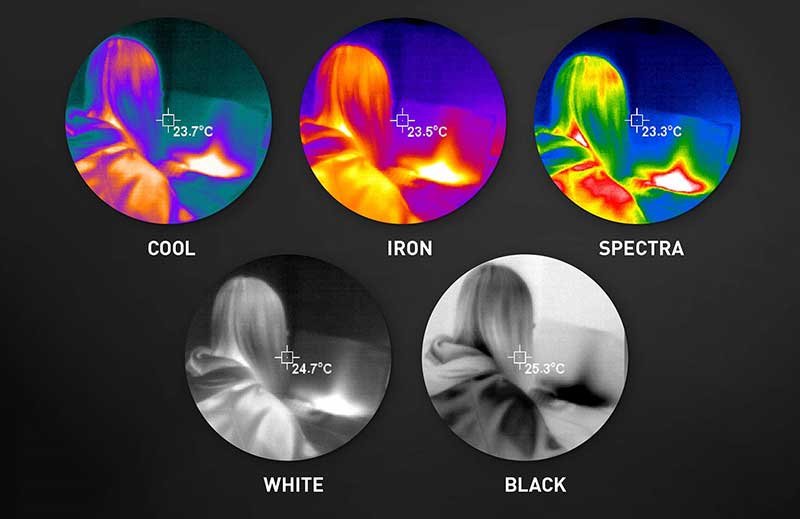

Detailed anatomy of an infrared camera

By Sat Sandhu, Fluke

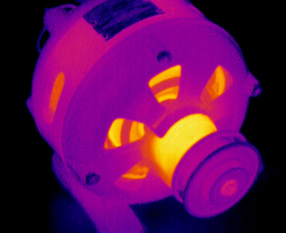

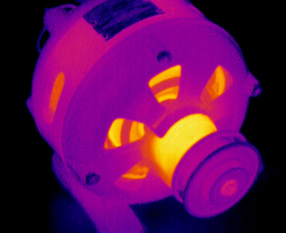

Infrared cameras, also called thermal imagers, are useful for troubleshooting motor problems as well as for monitoring motor condition for preventative maintenance in power generation, manufacturing and commercial plants. Thermal images of motors reveal their operating condition as indicated by surface temperature. Such condition monitoring is important as a way to avert many unexpected motor malfunctions in systems that are critical to manufacturing.

The onset of motor failures can often be detected by a variety of techniques, including vibration, ultrasound and thermal imaging.

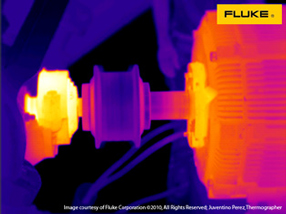

Thermal image of machinery

Why thermal imaging?

Thermal imaging is an effective way to assess equipment condition. Thermal imaging enables you to:

What to scan?

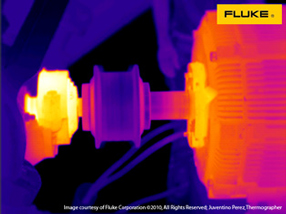

To get started in building heat profiles of your motors, it is a best practice to capture good quality infrared images when the motors are running under normal operating conditions. That gives you baseline measurements of the temperature of components. An infrared camera can capture temperatures of all the critical components: motor, shaft coupling, motor and shaft bearings, and the gearbox.

When you are working with low electrical loads, the indications of a problem may be subtle. Thus a minimum of 40% of design load is recommended (National Fire Protection Association NFPA 70B), and the higher the load, the better. When inspecting in low load situations, be sure to note all possible problems, even if they reflect only a small temperature difference. As a load increases, the temperature will increase too and if a problem exists, expect greater temperature differences at higher loads.

Coupling: This image shows an alignment issue on a motor coupling.

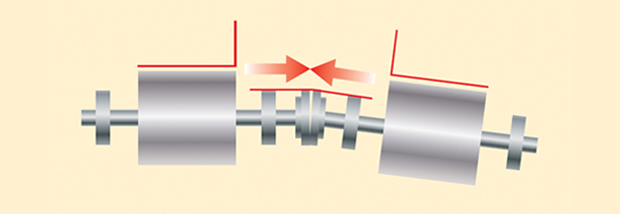

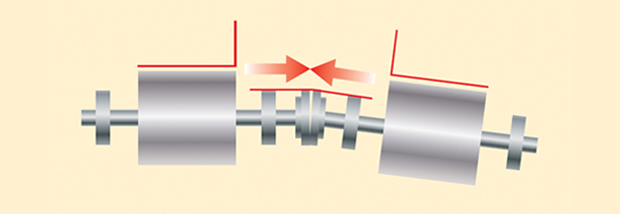

Angular misalignment

The centerline of the two shafts intersect are not parallel.

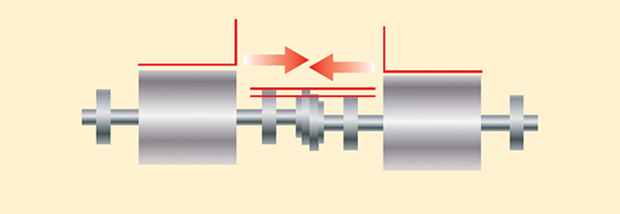

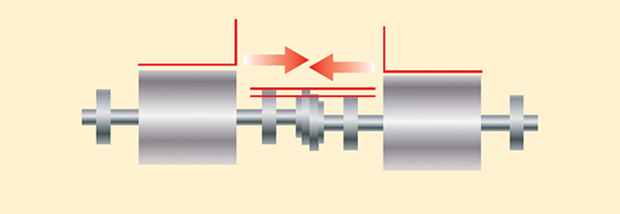

Combo: This heat pattern indicates an operational motor.

Parallel misalignment

The centerline of the two shafts are parallel but not concentric.

All motors should list the normal operating temperature on the nameplate. Abnormal temperatures, which will show up on a thermal imaging inspection, can be an indication of:

Inadequate cooling because of insufficient air flow. Clearing this issue may only require minor cleaning on the air intake grills.

Power quality issues such as unbalanced voltage or overload or harmonics. All of these will cause excessive heat dissipation.

Impending bearing failure. An overheating bearing is an indication of an impending bearing failure. Bearing condition degrade for a number of reasons:

Insulation failure. With failing insulation of the motor windings the overall motor temperature increases this overheating causes failures and reduces insulation time.

Shaft misalignment. Most misalignment cases are a combination of parallel and angular misalignment (see images above).

Creating regular inspection routes that include thermal images of all critical motor/drive combinations and tracking to those baseline images will help you determine whether a hotspot is unusual or not, and help you verify if the repairs were successful.

Click on a category to view a selection of compatible accessories with the Fluke Ti480 PRO 60Hz Infrared Camera, 640 x 480.

| Key Features | |

| Infrared Resolution | 640 x 480 (307,200 pixels) |

| SuperResolution | Yes, in software. Captures and combines 4x the data to create a 1280 x 960 image |

| IFOV with standard lens (spatial resolution) | 0.93 mRad, D:S 1065:1 |

| Field of View | 34 x 24° |

| Minimum Focus Distance | Approximately 6" (15 cm) |

| MultiSharp Focus | Yes, focused near and far, throughout the field of view |

| LaserSharp Auto Focus | Yes, for consistently in-focus images. Every. Single. Time |

| Laser Distance Meter | Yes, calculates distance to the target for precisely focused images and displays distance on screen |

| Advanced Manual Focus | Yes |

| Wireless Connectivity | Yes, to PC, iPhone® and iPad® (iOS 4s and later), Android™ 4.3 and up, and WiFi to LAN (where available) |

| Fluke Connect App Compatible | Yes, connect your camera to your smartphone, and images taken automatically upload to the Fluke Connect app for saving and sharing |

| Fluke Connect Assets | Through the desktop, assign images to assets, easily compare measurement types in one location and create reports |

| Fluke Connect Instant Cloud Upload | Yes, connect your camera to your building’s WiFi network, and images taken automatically upload to the Fluke Connect system for viewing on your smartphone or PC |

| Fluke Connect Instant Server Upload | Yes |

| IR-Fusion technology | Yes, adds the context of the visible details to your infrared image |

| Ruggedized Touchscreen Display | 3.5" (8.89 cm) landscape, 640 x 480 LCD |

| Ergonomic Design | Pistol-grip design for one-handed use |

| Thermal Sensitivity (NETD) | ≤0.05°C at 30°C target temperature (50 mK) |

| Level and Span | Smooth auto and manual scaling |

| Touchscreen Adjustable Level/Span | Yes. Span and level can be easily and quickly set by simply touching the screen |

| Fast Auto-Rescale in Manual Mode | Yes |

| Span | Minimum in manual mode: 2.0°C (3.6°F) Minimum in in auto mode: 3.0°C (5.4°F) |

| Built-in Digital Camera (Visible Light) | 5 MP |

| Laser Pointer | Yes |

| LED Light (Torch) | Yes |

| Digital Zoom | 2x and 4x |

| Data Storage and Image Capture | |

| Extensive Memory Options | Removable 4 GB micro SD memory card, 4 GB internal flash memory, save to USB flash drive capability, upload to Fluke Cloud™ for permanent storage |

| Image Capture, Review, Save Mechanism | One-handed image capture,review, and save capability |

| Image File Formats | Non-radiometric (.bmp) or (.jpeg) or fully-radiometric (.is2); no analysis software required for non-radiometric (.bmp, .jpg and .avi) files |

| Memory Review | Thumbnail and fullscreen review |

| Software | SmartView® software - full analysis and reporting software and Fluke Connect® system |

| Export File Formats with SmartView® Software | Bitmap (.bmp), GIF, JPEG, PNG, TIFF |

| Voice Annotation | 60 seconds maximum recording time per image; reviewable playback on camera, optional bluetooth headset available but not required |

| IR-PhotoNotes™ | Yes (5 images) |

| Text Annotation | Yes |

| Video Recording | Standard and radiometric |

| File Formats Video | Non-radiometric (MPEG - encoded .AVI) and fully-radiometric (.IS3) |

| Streaming Video (Remote Display) | Yes, see the live stream of the camera display on your PC, smartphone, or TV monitor. Via USB, WiFi hotspot, or WiFi network to SmartView® software on a PC; via WiFi hotspot to the Fluke Connect® app on a smartphone; or via HDMI to a TV monitor |

| Remote Control Operation | Yes, through SmartView® software or Fluke Connect® mobile app |

| Auto Capture (Temperature and Interval) | Yes |

| Temperature Measurement | |

| Temperature Measurement Range (Not Calibrated Below -10°C) | ≤14 to 1832°F (-10 to 1000°C) |

| Accuracy | ±2°C or 2% (at 25°C nominal, whichever is greater) |

| Thermal Sensitivity (NETD) | ≤0.05°C at 30°C target temp (50 mK) |

| On-Screen Emissivity Correction | Yes (both value and table) |

| On-Screen Reflected Background Temperature Compensation | Yes |

| On-Screen Transmission Correction | Yes |

| Line Temperature Graph | Yes |

| Smart Lenses | |

| Macro-25 Micron Lens: 25 MAC2 | Yes |

| 2 x Telephoto Lens: TELE 2 | Yes |

| 4 x Telephoto lens: TELE4 | Yes |

| Wide angle lens: WIDE 2 | Yes |

| Color Palettes | |

| Standard | 9: rainbow, ironbow, blue-red, high contrast, amber, amber inverted, hot metal, grayscale, grayscale inverted |

| Ultra Contrast™ | 9: rainbow, ironbow, blue-red, high contrast, amber, amber inverted, hot metal, grayscale, grayscale inverted |

| General Specifications | |

| Color Alarms (Temperature Alarms) | High temperature, low temperature, and isotherms (within range) |

| Infrared Spectral Band | 7.5 μm to 14 μm (long wave) |

| Temperature | Operating: 14 to 122°F (-10 to 50°C) Storage: -4 to 122°F (-20 to 50°C) without batteries |

| Relative Humidity | 10 to 95% non-condensing |

| Center-Point Temperature Measurement | Yes |

| Spot Temperature | Hot and cold spot markers |

| User-Definable Spot Markers | 3 user-definable spot markers |

| Battery | Type: 2 x lithium ion smart battery packs with five-segment LED display to show charge level Life: 2 to 3 hours per battery (Actual life varies depending on settings and usage) Charge time: 2.5 hours to full charge Charging system: Two-bay battery charger or in-imager charging |

| AC Operation | AC operation with included power supply (100 to 240 V AC, 50/60 Hz) |

| Power Saving | User selectable sleep and power off modes |

| Safety | IEC 61010-1: Overvoltage category II, Pollution Degree 2 |

| Electromagnetic Compatibility | IEC 61326-1: Basic EM environment. CISPR 11: Group 1, Class A |

| US FCC | CFR 47, Part 15 Subpart C Sections 15.207, 15.209, 15.249 |

| Vibration | 0.03 g2/Hz (3.8 g), 2.5 g IEC 68-2-6 |

| Shock | 25 g, IEC 68-2-29 |

| Drop | Engineered to withstand 6.5' (2 m) drop with standard lens |

| Enclosure Rating | IEC 60529: IP54 (protected against dust, limited ingress; protection against water spray from all directions) |

| Dimensions | 10.9 x 4.8 x 6.5" (27.7 x 12.2 x 16.7 cm) |

| Weight | 2.3 lbs (1.04 kg) |

|

|

|

||

| Model | Fluke Ti480 PRO | Fluke Ti401 PRO | Fluke Ti300+ | |

|---|---|---|---|---|

| Infrared Resolution | 640 x 480 (307,200 pixels) | 640 x 480 (307,200 pixels) | 320 x 240 (76,800 pixels) | |

| Super Resolution | Yes, in software. Captures and combines 4x the data to create a 1280 x 960 image | |||

| IFOV (Spatial Resolution) | 0.93 mRad | 0.93 mRad | 1.85 mRad | |

| Field of View | 34 x 24° | 34 x 24° | 34 x 24° | |

| Distance to Spot | 1065:1 | 1065:1 | 532:1 | |

| Thermal Sensitivity* | ≤0.05 at 30°C target temperature (50 mK) | ≤0.075 at 30°C target temperature (75 mK) | ≤0.075 at 30°C target temperature (75 mK) | |

| Temperature Range | -4 to 1832°F (-20 to 1000°C) | -4 to 1202°F (-20 to 650°C) | -4 to 1202°F (-20 to 650°C) | |

| MultiSharp™ Focus | ||||

| LaserSharp™ Auto Focus | LaserSharp™ Auto Focus for consistently in-focus images | |||

| Manual Focus | ||||

| Laser Distance Meter | Yes, calculates distance to the target for precisely focused images and displays distance on screen | |||

| Optional Lenses | Pre-calibrated smart optional lenses: wide angle, 2x and 4x telephoto, macro-25 micron | |||

| Wireless Connectivity** | Fluke Connect™ app compatible. Wireless connectivity to PC, iPhone® and iPad® (iOS 4s and later), Android™ 4.3 and up, and WiFi to LAN | |||

| IR-Fusion® | Five modes of image blending (AutoBlend™ mode, Picture-in- Picture (PIP), IR/Visible alarm, Full IR, Full visible light) add the context of the visible details to your infrared image | |||

| Display | 3.5" touchscreen 640 x 480 LCD | 3.5" touchscreen 640 x 480 LCD | 3.5" touchscreen 640 x 480 LCD | |

| Design | Pistol-grip design for one-handed use | |||

| Frame Rate | 60 or 9 Hz versions | 60 or 9 Hz versions | 60 or 9 Hz versions | |

| Software | Full analysis and reporting software with access to Fluke Connect desktop | |||

| Voice Annotation | 60 seconds maximum recording time per image, reviewable playback on camera; Bluetooth headset optional, but not required | |||

| Text Annotation | Yes, including standard shortcuts as well as user programmable options | |||

| Video Recording | Standard and radiometric | |||

| Streaming Video (Remote Display) | Yes, see the live stream of the camera display on your PC, smartphone, or TV monitor. Via USB, WiFi hotspot, or WiFi network to Fluke Connect Desktop software on a PC; via WiFi hotspot to the Fluke Connect™ app on a smartphone; or via HDMI to a TV monitor | |||

| Remote Control Operation | Yes, through Fluke Connect™ mobile app | |||

| Alarms | High temperature, low temperature, and isotherms (within range) | |||

| Warranty | Two-years (standard), extended warranties are available | |||

*Best possible **Fluke Connect™ not available in all countries

Fluke engineers have delivered an innovative mobile platform and tool that helps solve everyday problems, allowing you to instantly document measurements, retrieve historical data, and share live measurements with your team. All handled by the Android™ or iOS smart phone you already carry.

Fluke Connect with ShareLive™ video call is the only wireless measurement system that lets you stay in contact with your entire team without leaving the field. The Fluke Connect mobile app is works with over 20 different Fluke products - the largest suite of connected test tools in the world.

Make the best decisions faster than ever before by viewing temperature, mechanical, electrical and vibration measurements for each equipment asset in one place. Get started saving time and increasing your productivity.

Whether you choose a simple point-and-shoot model or a high-end thermal imager with all the bells and whistles, here are some key features and specs you should consider:

With a variety of focus mechanisms to choose from, it is important to take into account your skill level as well as the application in selecting a focus type. Here are the common focus mechanisms:

The highest and lowest temperature you encounter in your inspection determines the temperature range you need from your thermal imager. Or, select a camera with a wide temperature range that automatically selects the range based on your scene, or allows you to manually select the temperature range.

A camera that lets you change lenses increases your versatility, allowing you to inspect many more types of equipment and situations. There are lots of choices for lots of applications—standard, wide angle, telephoto, and macro.

Save infrared and digital images and in some cases voice notes to internal memory, a removable SD card, or to a USB flash drive. It’s important to have the flexibility to save images and additional related data to different media for backup or sharing.

Slight differences are easier to see with a monochromatic palette, such as grayscale or amber. High contrast palettes can make it easier to quickly find obvious anomalies. You should be able to change the palette in the camera or in the software.

Use these to quickly highlight areas outside your normal temperature ranges.

Low emissivity surfaces, such as shiny metals, can reflect infrared energy from other objects and throw off your image and your measurement accuracy. So, look for the option to adjust parameters when choosing an imager.

Mark specific temperatures on your image to compare simultaneous temperatures from multiple points on the same image.

Look for a battery with useful features such a charge level indicator. Nothing is worse than starting an inspection with no idea of the battery status. Also consider long battery life and quick charging ability.

Check out the different color palettes available on your thermal imager!

View your home through the eyes of a thermal imager and and see where the hot and cold spots are.

By Sat Sandhu, Fluke

Electronic circuits and components come in a variety of shapes and forms. All electronics operate with current flowing, which in turn leads to power dissipation. This power dissipation manifests itself primarily in the form of heat. Hence a key factor in the design, tests, verification and troubleshooting of all electronics, is heat management. With increasing circuit complexity and or reduction in size, heat management of electronics is taking on a more significant role in the design phase and also in the subsequent phases of test, verification and troubleshooting.

Thermal imaging cameras (TI) are an ideal tool to use in mapping out the heat patterns on electronic circuits and components. Two major advantages of Thermal imaging over contact temperature measurement devices are:

If you would like to learn more about:

Detailed anatomy of an infrared camera

By Sat Sandhu, Fluke

Infrared cameras, also called thermal imagers, are useful for troubleshooting motor problems as well as for monitoring motor condition for preventative maintenance in power generation, manufacturing and commercial plants. Thermal images of motors reveal their operating condition as indicated by surface temperature. Such condition monitoring is important as a way to avert many unexpected motor malfunctions in systems that are critical to manufacturing.

The onset of motor failures can often be detected by a variety of techniques, including vibration, ultrasound and thermal imaging.

Thermal image of machinery

Why thermal imaging?

Thermal imaging is an effective way to assess equipment condition. Thermal imaging enables you to:

What to scan?

To get started in building heat profiles of your motors, it is a best practice to capture good quality infrared images when the motors are running under normal operating conditions. That gives you baseline measurements of the temperature of components. An infrared camera can capture temperatures of all the critical components: motor, shaft coupling, motor and shaft bearings, and the gearbox.

When you are working with low electrical loads, the indications of a problem may be subtle. Thus a minimum of 40% of design load is recommended (National Fire Protection Association NFPA 70B), and the higher the load, the better. When inspecting in low load situations, be sure to note all possible problems, even if they reflect only a small temperature difference. As a load increases, the temperature will increase too and if a problem exists, expect greater temperature differences at higher loads.

Coupling: This image shows an alignment issue on a motor coupling.

Angular misalignment

The centerline of the two shafts intersect are not parallel.

Combo: This heat pattern indicates an operational motor.

Parallel misalignment

The centerline of the two shafts are parallel but not concentric.

All motors should list the normal operating temperature on the nameplate. Abnormal temperatures, which will show up on a thermal imaging inspection, can be an indication of:

Inadequate cooling because of insufficient air flow. Clearing this issue may only require minor cleaning on the air intake grills.

Power quality issues such as unbalanced voltage or overload or harmonics. All of these will cause excessive heat dissipation.

Impending bearing failure. An overheating bearing is an indication of an impending bearing failure. Bearing condition degrade for a number of reasons:

Insulation failure. With failing insulation of the motor windings the overall motor temperature increases this overheating causes failures and reduces insulation time.

Shaft misalignment. Most misalignment cases are a combination of parallel and angular misalignment (see images above).

Creating regular inspection routes that include thermal images of all critical motor/drive combinations and tracking to those baseline images will help you determine whether a hotspot is unusual or not, and help you verify if the repairs were successful.

Click on a category to view a selection of compatible accessories with the Fluke Ti480 PRO 60Hz Infrared Camera, 640 x 480.